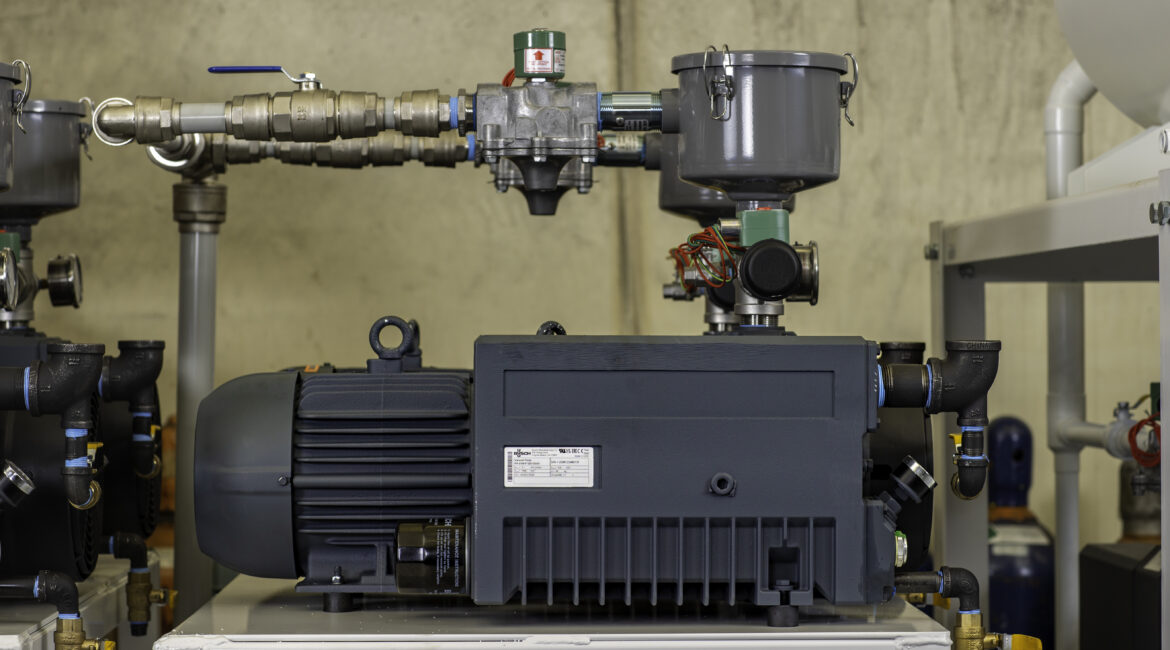

Rotary pumps are essential to the smooth operation of countless industrial and commercial systems—from vacuum packaging to fluid transfer in manufacturing. When these pumps begin to fail, it can disrupt operations, reduce efficiency, and increase maintenance costs.

While regular maintenance can extend the life of your equipment, even the best rotary pumps eventually reach the end of their service life. Knowing the early warning signs of pump failure can help you avoid unplanned downtime and costly emergency repairs.

Below are four key signs your rotary pump may be due for replacement.

Here are some basic signs:

1. The Pump Is Over 10 Years Old

Long-term use is one of the most common predictors of performance issues.

Most rotary pumps perform reliably for 7–10 years with regular maintenance. After a decade of operation, components begin to wear down, internal tolerances shift, and overall efficiency drops—even if the pump seems to be functioning normally.

Signs of aging may include:

-

Slower start-up times

-

Increased energy consumption

-

Inconsistent system performance

-

Growing maintenance frequency

If your rotary pump is more than 10 years old and performance is declining, it’s time to start planning for a replacement.

2. Inconsistent or Unresponsive Pump Speed

If your rotary pump is no longer responding to speed adjustments or seems sluggish during operation, internal mechanical issues could be to blame.

Common culprits include:

-

A loose or worn drive shaft

-

Low oil levels affecting the transmission system

-

Damaged internal bearings or rotors

If correcting oil levels and checking connections doesn’t resolve the issue, it’s likely the pump is nearing the end of its useful life.

3. Irregular or Inconsistent Pressure Output

Maintaining stable pressure is a critical function of any rotary pump. If you’re experiencing fluctuations in vacuum or pressure, especially after replacing parts like sealing rings, the issue may be more than just routine wear and tear.

Persistent pressure inconsistencies could point to:

-

Internal vacuum leaks

-

Rotor damage

-

Failing seals beyond repair

When troubleshooting no longer restores proper performance, it may be more cost-effective to invest in a new pump system.

4. Excessive Vibration or Noise

Some vibration is normal during rotary pump operation. However, sudden increases in vibration or new, abnormal noises—such as grinding, whining, or rattling—can be signs of serious internal damage.

These symptoms may indicate:

-

Worn bearings or gears

-

Shaft misalignment

-

Cracked impellers

-

Mounting bolts loosening due to excessive wear

While some of these issues may be repairable, persistent or worsening vibration typically signals the need for replacement.

Trust GlobalVac & Air for Reliable Pump Solutions

At GlobalVac & Air, we’ve been supplying high-performance vacuum pumps, compressed air systems, and pneumatic equipment for over 30 years. Whether you’re troubleshooting an aging rotary pump or exploring a system upgrade, our experts can help you find the right solution.